SUPPLY OF RELATED

PRODUCTS AND SERVICES

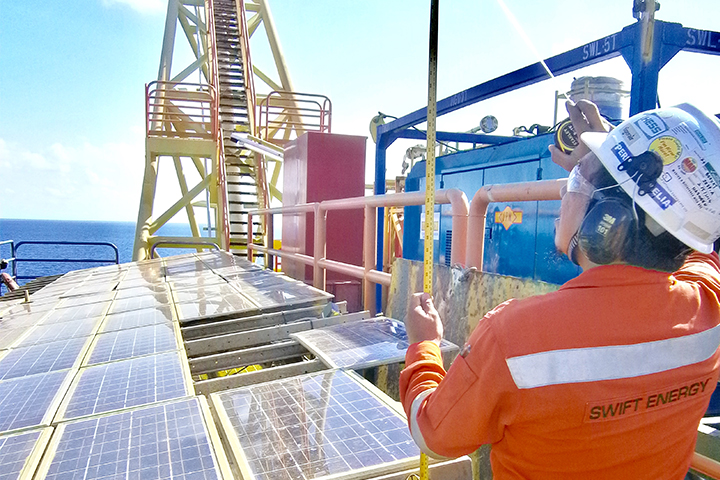

We are principally involved in the provision of industrial automation and power system focusing on process control, Ex solar PV, power distribution, and other systems mainly serving customers in the O&G, as well as grain products, edible oils, and food manufacturing industries. We are also involved in the supply of related products and services comprising the distribution of power and industrial electrical products, as well as the provision of technical services.