SWIFT PROCESS CONTROL

SYSTEMS

Process control systems are the cornerstone of industrial automation that control all aspects of processing within a manufacturing or processing plant or facility. This system allows organisations to monitor, regulate, and streamline their production processes with precision and reliability. A process control system may be based on a SCADA or a DCS. The SCADA or DCS controls sub-controllers which are either RTU or PLC that control the processes of various subsections of a plant or facility. Through the HMI hardware and software, personnel can interact with the system as and when required.

We design and develop the system, program all the relevant application software and integrate communications for the SCADA, DCS, PLC, RTU, and HMI, and install, assemble, and integrate them with other industrial sensors, instrumentations and other devices. The hardware and systems software for the DCS, SCADA, PLC, RTU, and HMI are purchased from third parties, while we will program the application software as well as assemble and integrate all the devices within enclosures that are fabricated in-house by us. Our process control systems are sold under our “Swift Energy” brand name.

PRODUCTS

Industrial Process Control Systems (IPCS)

SWIFT offers the most comprehensive range of system integration services for industrial. Our team provides expertise to oil & grains manufacturers, oil & gas industries, utilities, food & beverage manufacturers, and process chemical plants. Our team of automation experts provides services including control & instrumentation design, software development, networking support, legacy system migration, and commissioning.

Wireless Mobile Operator Station

Network is connected securely to the process control network. Operators equip with Industrial Process Control Tablet able to monitor and control the plant while roaming.

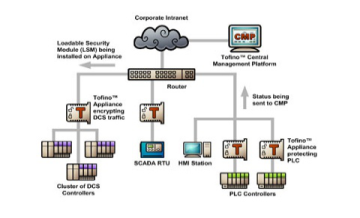

Industrial Information & Network Security

- Process Control System Network Review

- Process Control System Vulnerability Assessment

- Design of Secured Process Control Systems

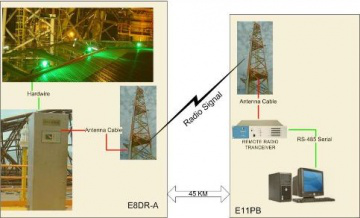

Remote Telemetry Unit (RTU) Systems

- Monitor and control field digital and analog parameter

- Transmit all the data to the Central Monitoring Station via Radio modem